The Problem: Drowning in Picking Lists and Inventory Reports

If you manage warehouse operations or distribution centers, you know the drill. Every day brings hundreds of picking lists, packing slips, receiving documents, and inventory reports. Someone has to read them, extract key details, update stock levels, and flag discrepancies.

This work is necessary but exhausting. A warehouse coordinator might spend hours each week:

- Extracting SKUs and quantities from PDF picking lists

- Updating inventory records from receiving documents

- Cleaning up OCR output from scanned packing slips

- Sorting orders by priority, zone, or shipping method

- Generating reports on fulfillment accuracy and stock levels

The volume is high, the work is repetitive, and mistakes are costly. A missed SKU or incorrect quantity can cascade into picking errors, inventory discrepancies, or customer complaints.

Why These Tasks Are Static

Most of these warehouse tasks follow predictable, rule-based patterns. They don't require judgment, negotiation, or strategic thinking. They require consistency and accuracy.

Consider inventory tracking. You have a picking list with 50 line items. You have a packing slip with SKUs and quantities. Your job is to match them, update stock levels, and flag discrepancies. The logic is deterministic: does this SKU match this order? Does the quantity picked match the quantity ordered?

The same applies to extracting bin locations from PDFs, normalizing product codes across systems, or categorizing orders by fulfillment zone. These are mechanical tasks with clear inputs and outputs.

Why Local AI Is a Good Fit

Local AI—models that run on your own hardware, not in the cloud—excels at exactly this kind of work. Here's why it makes sense for warehouse operations:

- High volume: Warehouses generate massive amounts of documents and data. Local AI can process hundreds of picking lists or inventory reports in a single batch without per-document cloud API costs.

- Deterministic outputs: You're not asking for creative writing or strategic advice. You're asking for field extraction, format normalization, and inventory updates—tasks where consistency matters more than reasoning.

- Privacy: Inventory data, order information, and customer details are proprietary. Running AI on-device means sensitive warehouse data never leaves your network.

- Offline operation: Warehouses and distribution centers don't always have reliable internet. Local AI works without connectivity.

Local AI isn't replacing your warehouse team. It's handling the mechanical, repetitive parts so your team can focus on exceptions, quality control, and operational improvements.

What Local AI Actually Does

Local AI can perform specific, mechanical actions within warehouse workflows:

- Document reading: Extract text from picking lists, packing slips, receiving documents, and inventory reports (PDF, Excel, CSV, or scanned documents)

- Field extraction: Pull order IDs, SKUs, product descriptions, quantities, bin locations, stock levels, and customer information

- Data cleaning: Normalize SKU formats, fix OCR errors, standardize product names across different systems

- Inventory updates: Compare current stock levels against incoming/outgoing orders, flag low stock alerts, identify missing or duplicate items

- Classification: Sort orders by priority, fulfillment zone, shipping method, or product category; categorize inventory by location or stock status

- Summarization: Generate structured reports on order fulfillment rates, inventory accuracy, picking efficiency, or stock replenishment needs

- Output formatting: Produce CSV files, JSON data, or spreadsheets for import into warehouse management systems

Important: Local AI assists the process but does not replace professional judgment or operational decisions. It handles the mechanical work. Your team handles exceptions, quality control, layout optimization, and staffing decisions.

Step-by-Step Workflow

Here's how a warehouse team might use local AI to automate inventory tracking and order processing:

Step 1: Prepare Documents

Collect the day's picking lists, packing slips, and inventory reports. These might be PDFs from your warehouse management system, Excel files with stock levels, or scanned receiving documents.

Step 2: Extract Key Fields

Run local AI to extract order IDs, SKUs, product descriptions, quantities, bin locations, and stock levels from each document. The model outputs structured data (CSV or JSON) with one row per item.

Step 3: Normalize Formats

Use local AI to standardize SKU formats, clean up product names, and fix common OCR errors (e.g., "1" vs "I", missing dashes in product codes).

Step 4: Update Inventory Records

Feed the extracted data into your inventory system. Local AI compares current stock levels against incoming/outgoing orders, flagging discrepancies: low stock alerts, missing items, or duplicate entries.

Step 5: Classify and Route Orders

Classify orders by priority (same-day, standard, backorder), fulfillment zone, or shipping method. This makes it easier for your warehouse team to optimize picking routes and batch similar orders.

Step 6: Generate Reports

Use local AI to produce a summary report: total orders processed, items picked, inventory adjustments needed, and fulfillment accuracy. Output as a spreadsheet or JSON file for your warehouse dashboard.

Step 7: Human Review

Your warehouse team reviews flagged discrepancies, resolves inventory exceptions, and makes decisions on stock replenishment or order prioritization. Local AI has done the mechanical work; your team handles the judgment calls.

Realistic Example

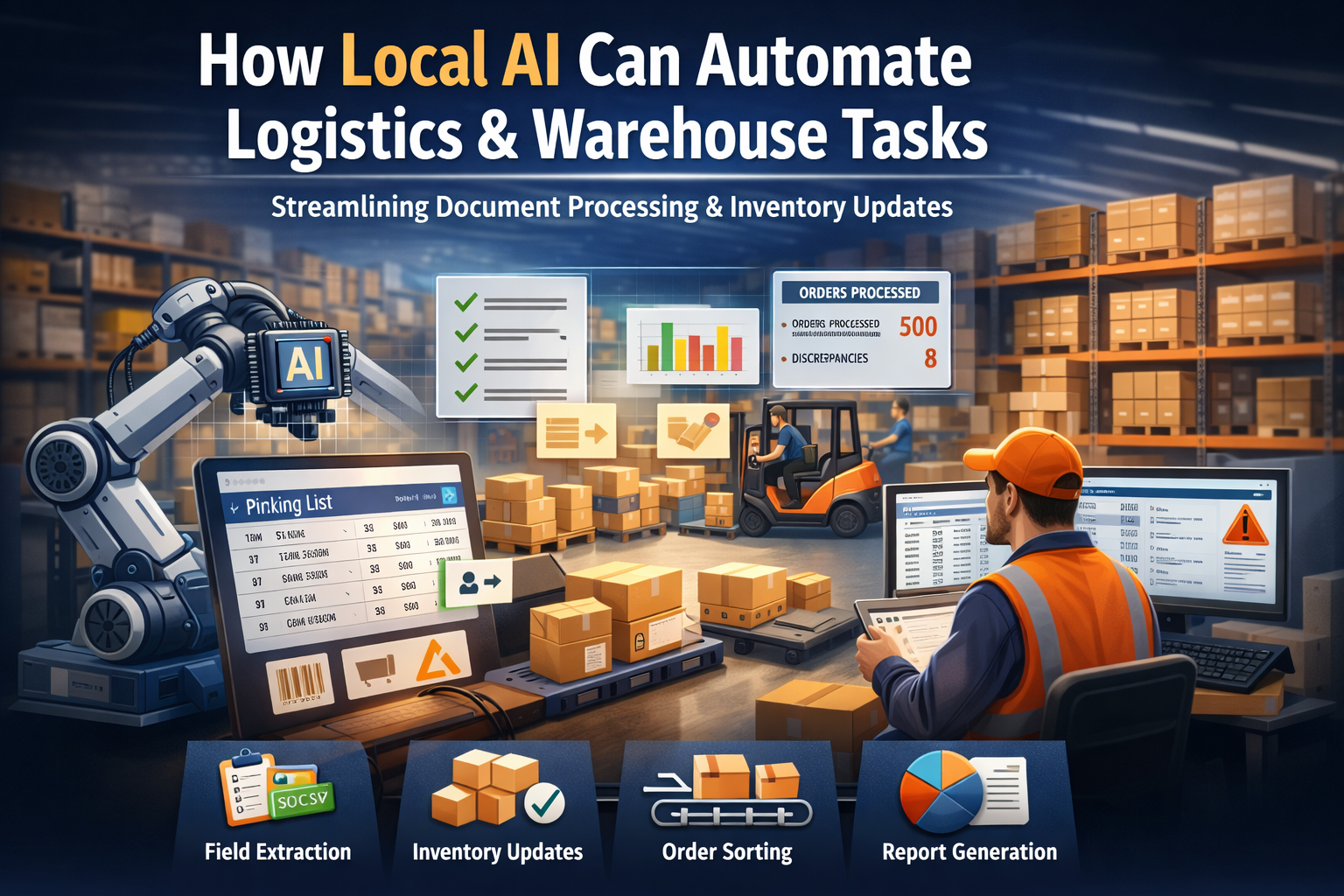

A mid-size distribution center processes 500 orders per day across two fulfillment zones. Each order generates a picking list with SKUs, quantities, and bin locations. Manually processing and updating inventory takes two warehouse coordinators about 3 hours per day.

They implement local AI to automate field extraction and inventory updates. The workflow now looks like this:

- Local AI processes 500 picking lists in 15 minutes, extracting all key fields

- The model normalizes SKU formats and product names, fixing 30–40 OCR errors per batch

- Inventory update script flags 8 discrepancies (low stock alerts, missing items)

- Coordinators spend 30 minutes reviewing flagged issues and adjusting stock levels

Total time: 45 minutes instead of 3 hours. The team now uses the saved time to focus on quality control, process improvements, and training new staff.

Limits: When NOT to Use Local AI

Local AI is not appropriate for warehouse tasks that require judgment, reasoning, or strategic decision-making. Do not use local AI for:

- Layout optimization or slotting: Determining the most efficient warehouse layout or product placement requires specialized algorithms and operational analysis, not language models.

- Staffing decisions: Deciding how many pickers to schedule, when to hire seasonal workers, or how to allocate labor requires human judgment and workforce management expertise.

- Exception handling: When an order is damaged, a customer requests a rush shipment, or inventory is missing, your team needs to assess the situation and make case-by-case decisions.

- Strategic planning: Forecasting demand, optimizing stock levels, or redesigning fulfillment processes require domain expertise and analytical tools beyond local AI's capabilities.

- Ambiguous or high-stakes situations: If the data is incomplete, contradictory, or involves significant financial or customer impact, human review is essential.

Local AI is a tool for mechanical, high-volume tasks. It does not replace warehouse expertise, operational thinking, or customer service.

Key Takeaways

- Local AI is effective for static, high-volume warehouse tasks like document processing, field extraction, and inventory updates

- It reduces time spent on repetitive work and minimizes errors in order fulfillment, inventory tracking, and stock management

- Running AI on-device keeps proprietary warehouse data private and works offline in distribution centers

- Local AI handles mechanical tasks but is not a replacement for human judgment, operational decisions, or exception management

- Best used for deterministic workflows where consistency and volume matter more than reasoning or negotiation

Next Steps

If you're considering local AI for warehouse automation, start by identifying your most repetitive, high-volume tasks. Look for workflows where you're manually extracting data from documents, updating inventory records, or generating fulfillment reports.

Test local AI on a small batch—50 picking lists or 100 packing slips—and measure the time saved. Focus on tasks where the logic is clear and the outputs are deterministic.

Local AI won't solve every warehouse challenge, but for the right tasks, it can free your team from hours of mechanical work and let them focus on what matters: quality control, process improvements, and customer satisfaction.